Process

1. 계약

고객에게서 받은 계약서 각팀별 검토하여 유관부서에 배포

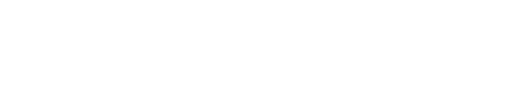

2. 설계 및 NC프로그램

고객이 제공한 엔지니어링 데이터 기반으로 공정프로세스 작성

3. 자재 절단

부품제작 공정서(SHOP ORDER) 에 기재된 자재사이즈 기준으로 절단진행

4. 성형

적당한 물리적 과정을 거쳐 일정한 모형으로 만드는 공정

5. 열처리

금속의 성질을 변화 시키기 위하여 열을 가하고 냉각시키는 공정

6. 가공

NC 프로그램 기반으로 고객도면 에 맞게 형상가공

7. 사상

표면을 다듬고 버(burr)나 가공미스매치(mismatch) 같은 불필요한 부분을 제거하는 공정

8. 검사

도면 요구 조건에 맞게 가공되었는지 3차원측정기를 이용하여 부품의 이상유무 판단

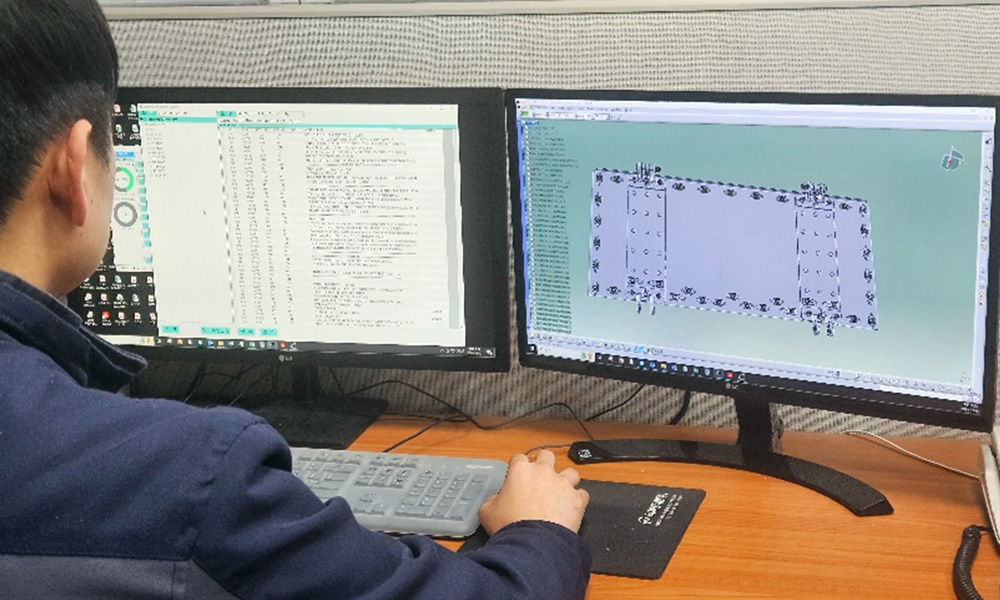

9. 화공

부품을 화학적으로 표면처리 하는 공정

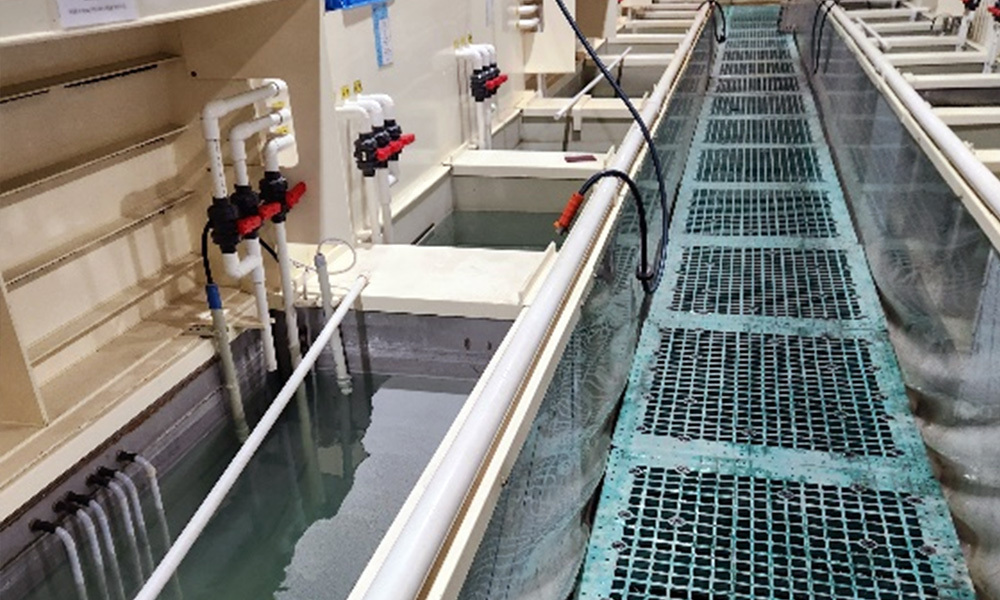

10. 페인트

제품의 바탕 보호를 위해 도장하는 공정

11. 조립

조립 지그를 이용하여 각각의 부품을 서로 결합하여 완제품을 만들어 내는 공정

12. 선적

고객사 발주에 맞춰 제품 인계